TEC CONTAINER

Cargo securing and lifting equipment since 1976

Get to know our cargo securing & handling systems

Own design and production from

more than 40 years of experience.

REQUEST MORE INFO

Your message has been sent!

We'll answer you as soon as posible

Thank you!

OUR PRODUCTS

Safety and Efficiency Solutions

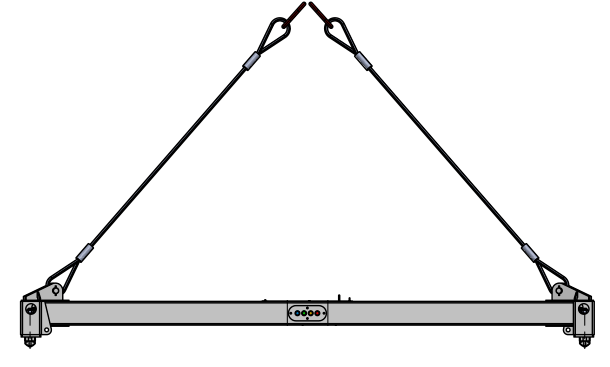

OVER HEIGHT FRAMES

Special Handling Equipment for Oversized containerized cargo.

ON SHORE POWER SUPPLY

We want to reduce the carbon footprint of ports maintaining full operations.

Our

values

SAFETY

Higher Safety factors

Decades of experience

Highly tested products

DNV, BV, SGS continuous inspections

Far beyond international laws

QUALITY

Continuous welding & certified welders

Our own production facilities

100% European manufacture

Certifications & instructions

After sales service in 80 countries

I+D

Taylor made solutions

Own patents

Our own designs

Top institutions Collaborations

Any crane, any port, any industry

WHY

TEC CONTAINER?

For reliability.

- On time deliveries

- Each machine is delivered with the complete documentation and certification according to each regulation.

- Continuous after sales support

Due to adaptability.

- We identify solutions to your operational and efficiency issues.

- We adapt our designs to each customer needs and requirements.

For prestige.

- TEC Container brand is guarantee of success.

- We have been working for 40 years with the most internationally recognized companies such as DP World, MSC or DNCS.

- Our products are at the forefront in their segments in more than 80 countries, always complying with the most recent regulations that guarantee safety at work, and adapting to new European regulations, such as the NTP for safety cages.

- European design and manufacturing: Made in Spain.

Because you are looking for efficiency and safety.

- All our designs are adapted to the specific operations of each customer, increasing the efficiency.

- We always use higher safety factors than those required by the market standards.

- Our products are used by people, and in certain cases, as the safety cages, the technicians are inside during the operation. Therefore, we always supply our equipment with the most prestigious certification seals and continuous external audits and inspections.

- Making lifting operations completely safe is our mission.