THE 20 ADVANTAGES OF THE RAM-REVOLVER SYSTEM FOR BULK CARGO INSIDE CONTAINERS

by Tec Container | Dec 5, 2016 | Container

For the past three years, bulk cargo exporting seaports have had an efficient alternative with obvious advantages for the environment: We are talking about the container loading and storage system: RAM REVOLVER®

ADVANTAGES BASED ON EFFICIENCY:

- The system allows the goods to be stored at source (at the mine) in the same closed REVOLVER containers to improve the preservation of the product until it is transported to seaport.

- Improved safety of the load in road transport as it is always protected. Shrinkages and losses disappear as REVOLVER containers have an airtight lid.

- Improved efficiency in transport as trucks are standard for container traffic. This increases the payload per trip.

- Improved storage at seaport because the containers can be stacked to await the arrival of the ship. This increases the material stored per square meter.

ENVIRONMENTAL BENEFITS:

- By keeping the load inside closed containers, any interaction with the environment is substantially enhanced, drastically reducing any dust cloud caused by the wind both at source and during transport, storage at the seaport and finally during the process of being loading to the ship.

- The storage of containers eliminates piles or stacks of material which reduces the load’s exposure to severe weather conditions.

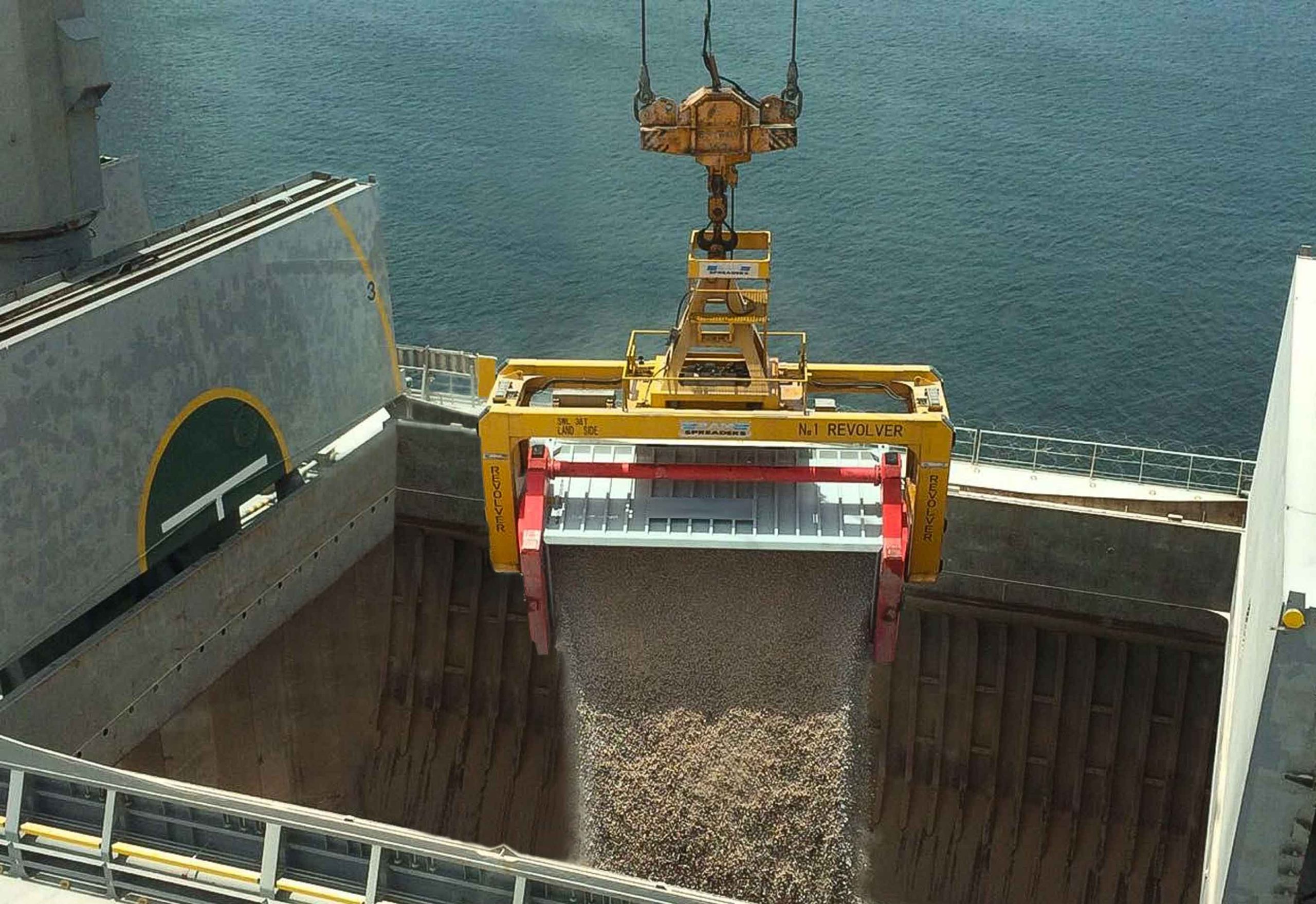

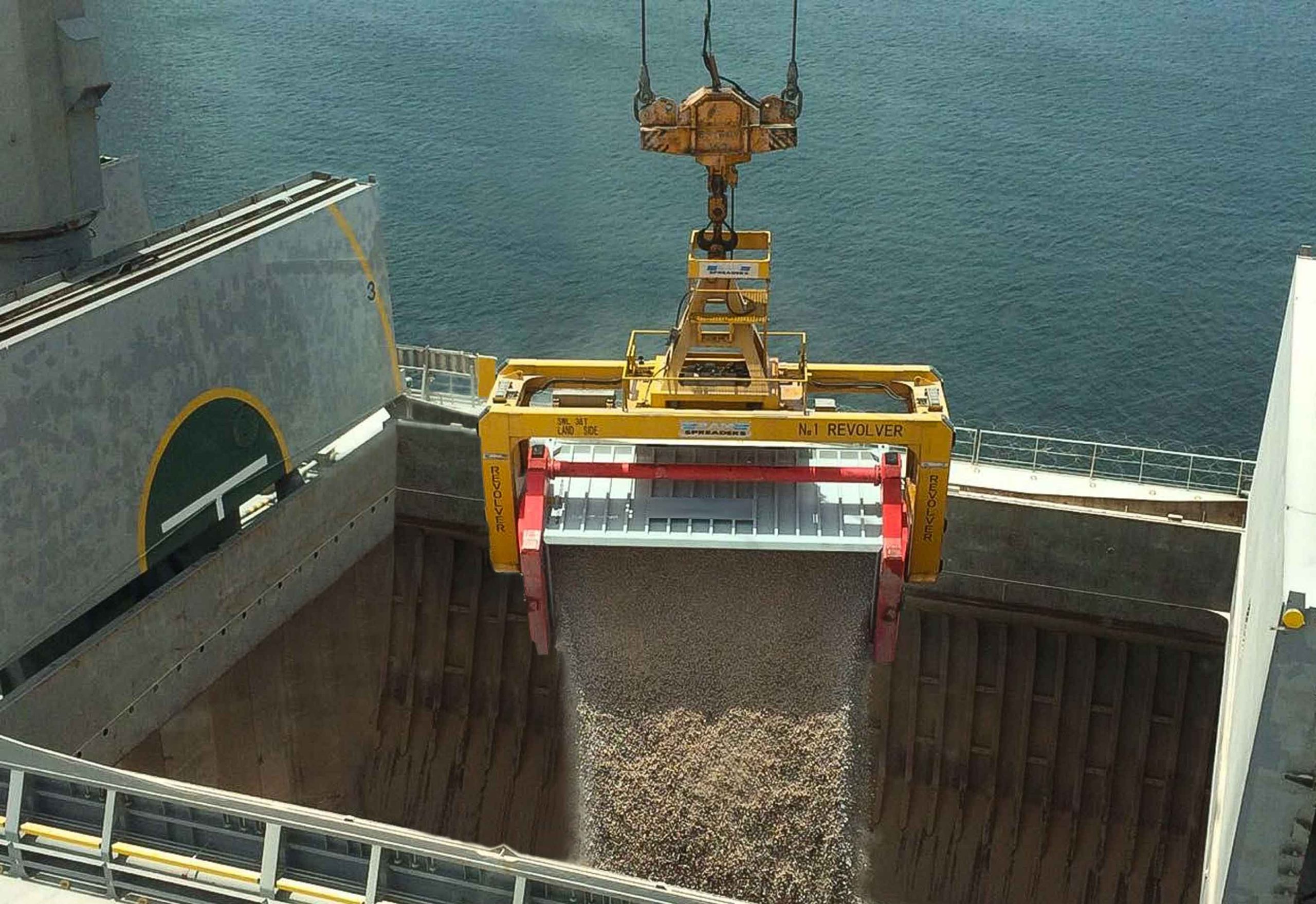

- The loading process is performed with the attached lid so that no load is lost during movement of the container to the ship’s hold. In addition, the container is emptied at the bottom of the ship’s hold, adding minimal energy thus minimising the cloud that forms when the load falls into the ship’s hold.

- A Hatch based Dust Suppression system that creates a curtain of water spray that prevents dust emission from within the hold of ships.

- Being a much cleaner and environmentally friendly system, it has easy access to environmental subsidies and aids.

- Being an ECO-FRIENDLY system, it provides immediate benefits to the Local community and its environment.

ADVANTAGES BASED ON ADDED VALUE:

- For container terminals, implementing the system is simple and inexpensive because the machines used for normal container traffic (Reach-Stackers, Cranes … etc.) are fully compatible with the REVOLVER system.

- For container terminals, implementing the system radically opens the possibilities to new traffic immediately expanding the range of new customers and providing a new value in operations to existing customers.

- Thanks to RAM – Revolver, a productivity of close to 1000 tonnes / hour/ crane is achieved in a very short period, so productivity is not reduced compared to traditional scoop operations or alternative expensive bulk loaders

- In terms of costs, the implementation of the REVOLVER system brings a 60% cost reduction compared to the traditional system of silos, conveyor belts, cranes and scoops, That is, the REVOLVER system is one third of the cost of traditional projects.

- The REVOLVER System does not require civil works or administrative permits.

- The training required for operators is simple as the use and maintenance is very similar to existing spreaders.

- The after sales service is integrated into the RAM Spreaders network (worldwide) and TEC Container network (in Spain and Portugal).

- Being an innovative system it has easy access to aids and subsidies for R & D and process improvement.

- Being an innovative system it has easy access to “public authorities” and to the media as a breakthrough at local level.

- Both the Spreader and the containers are likely to be sold to other terminals as second hand and recover some of the investment in the event of a reduced traffic situation. This does not happen with traditional facilities that remain unused “for life”.